Industrial Humidification Systems

Air humidification

Air humidification involves adding moisture to the air through specialized systems that raise the relative humidity in the environment. This process is especially crucial in industries where dry air can adversely impact production quality and working conditions.

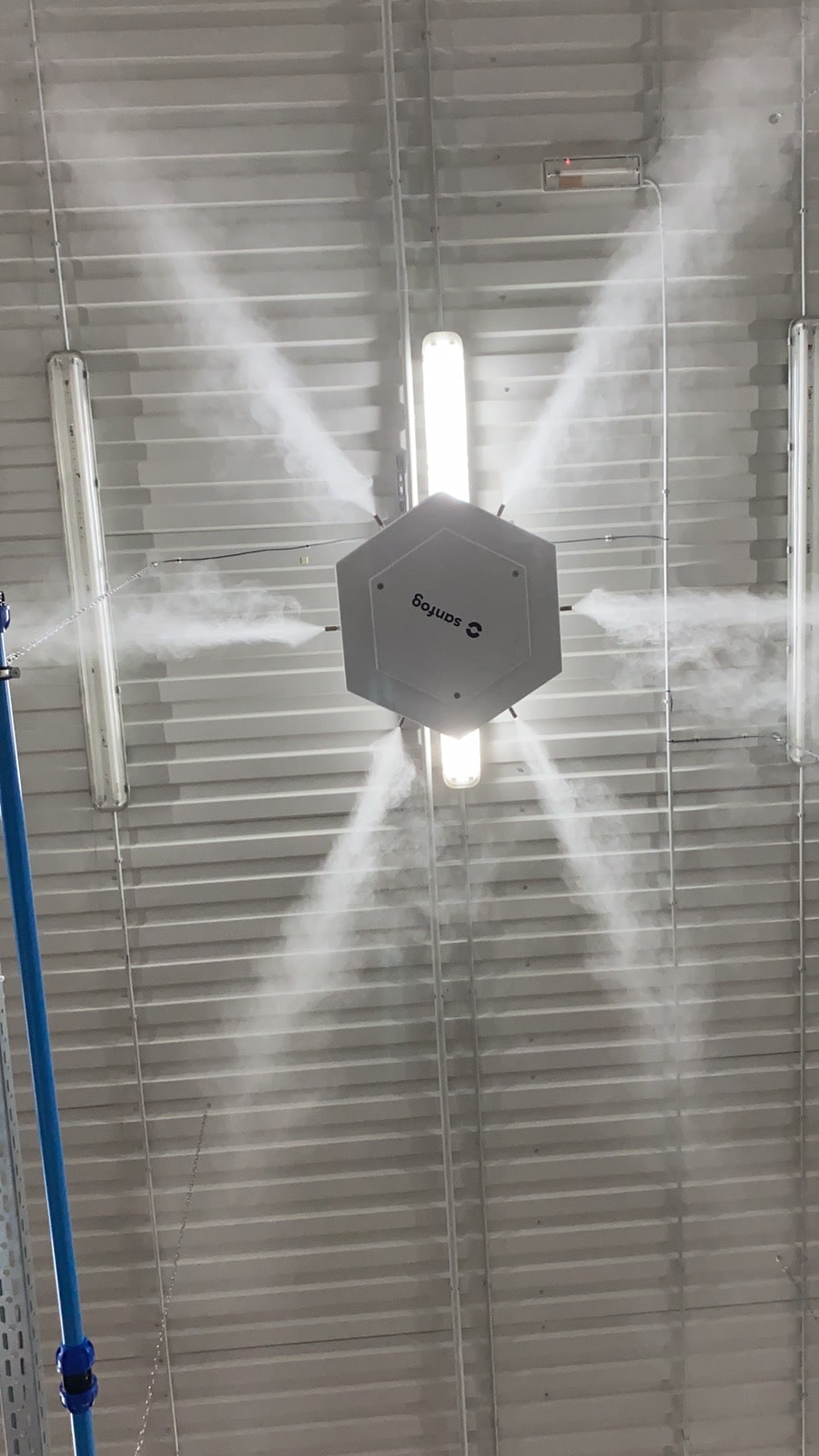

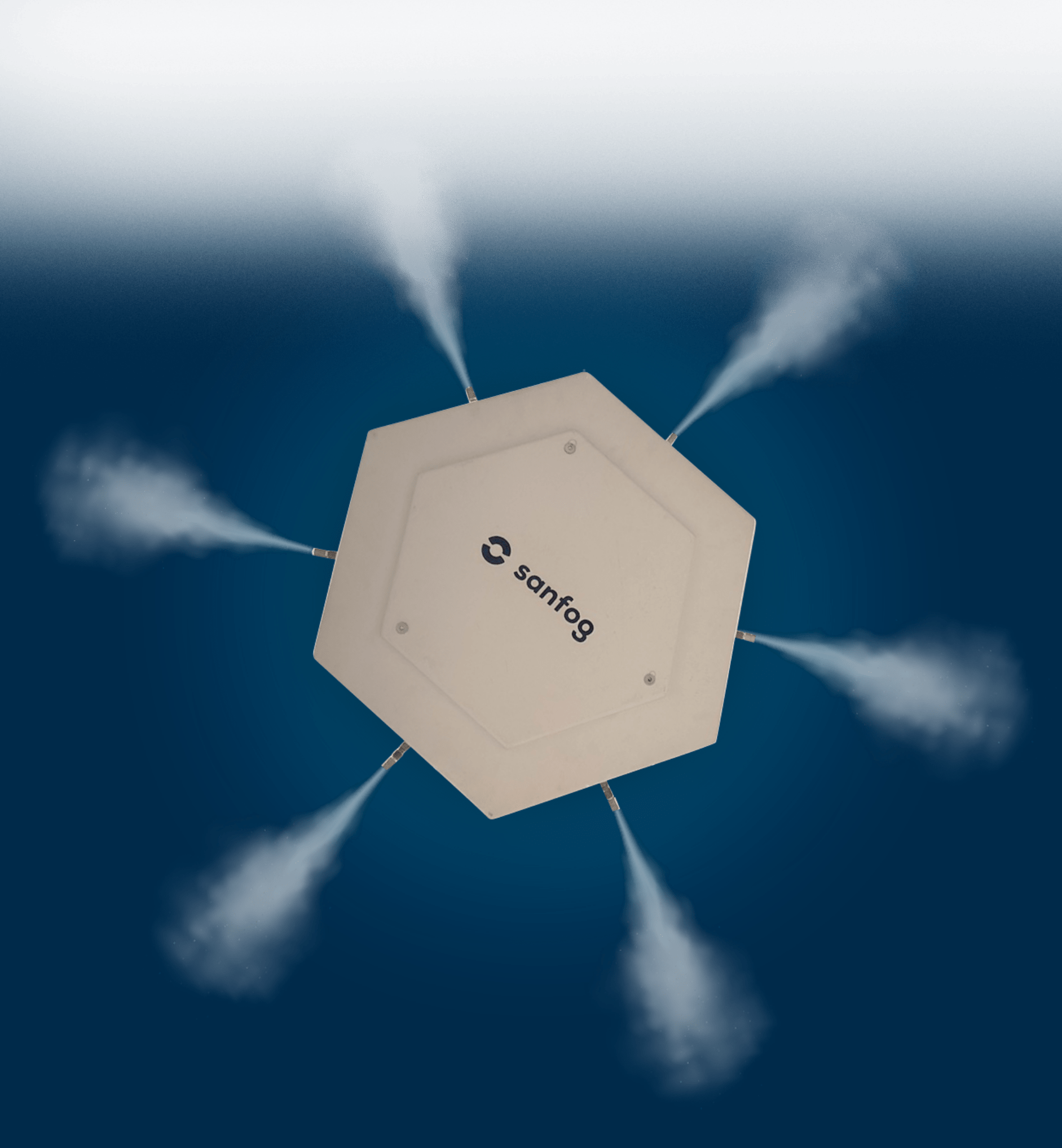

One of the most effective methods, humidification and adiabatic cooling utilize the natural evaporation of water to create an improved microclimate. This process is achieved without chemicals and at a low operating cost.

Industrial uses

Air humidification finds widespread application in diverse industrial sectors.

Electrotechnical Industry

Reliable ESD protection

The challenge of miniaturization and ESD

As electronic components become increasingly miniaturized, protection against electrostatic discharge (ESD) is more critical than ever. Modern electronic devices, printed circuit boards, and data components are highly sensitive to ESD— even a discharge as low as 100 V can cause irreversible damage.

Dry air, with a relative humidity below 40%, significantly increases the risk of electrostatic buildup, leading to equipment failures and higher repair costs.

Benefits of our humidification systems:

Eliminate ESD: Maintaining 50–55% relative humidity increases surface conductivity, preventing electrostatic charge buildup.

Protect Sensitive Components: A thin moisture layer on surfaces dissipates electrical charges, safeguarding delicate electronic parts.

Temperature Control: Our cold-water humidifiers can lower temperatures by up to 12°C, ensuring optimal working conditions.

Energy Efficiency: Reduced reliance on cooling systems leads to significant energy savings and lower operating costs.

Key processes protected by humidification:

1. Printed Circuit Board (PCB) Manufacturing

Soldering machines generate intense heat, drying out the air and increasing the risk of ESD.

Precise humidity control prevents this issue, ensuring consistent production quality.

2. Assembly & Handling

Dry air can lead to accidental discharges when handling ungrounded wires and components.

Our systems safeguard both employees and equipment from electrostatic risks.

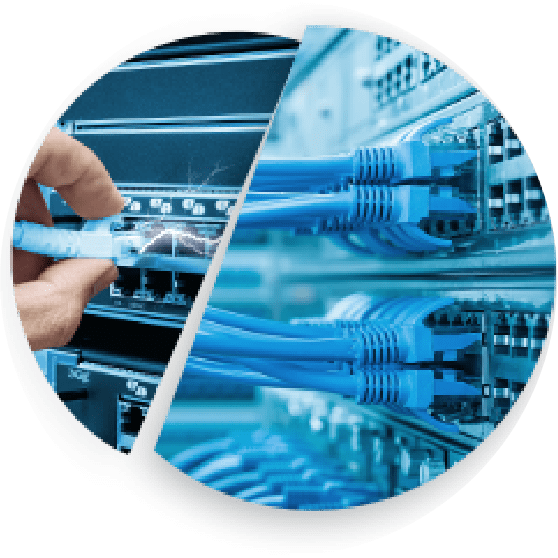

3. Data Centers

Low humidity can cause uncontrolled discharges during maintenance, potentially damaging sensitive components.

Maintaining optimal humidity prevents static buildup and protects critical infrastructure.

How does humidity control work?

Increased Conductivity: At 50–55% RH, moisture ions accumulate, enhancing surface conductivity and preventing electrostatic charge buildup.

Stable Conditions: Intelligent humidification maintains a consistent environment, eliminating fluctuations that could impact production quality.

Our solutions for the electrotechnical industry:

Precision Humidification: Ensures optimal conditions with an accuracy of ±3% RH.

Automated Systems: Advanced controls tailored to your specific needs.

Flexible Deployment: Modular solutions for production halls, data centers, and other facilities.

Energy Efficiency: Optimized performance reduces operating costs while providing maximum protection.

Proper humidity control is essential for protecting your equipment, enhancing production quality, and minimizing costs related to downtime and repairs. Contact us to discover how we can support your electronics business!

Laboratories

Presnosť, ochrana a efektivita

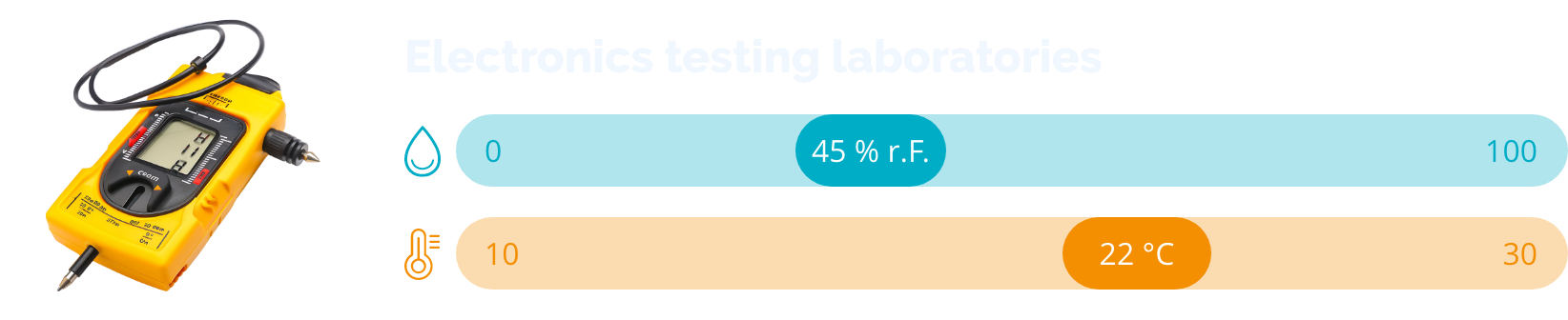

The importance of humidity control in laboratories

Maintaining precise humidity levels is essential for ensuring reliable test results, protecting sensitive instruments, and creating an optimal working environment.

Benefits of our humidification systems:

1. Accurate Testing:

Stable relative humidity eliminates external factors that can influence experiments.

Ensuring consistent and precise results in sensitive laboratory processes.

2. Equipment Protection:

Maintaining relative humidity at 50–55% RH prevents electrostatic charge buildup and contamination.

Extending the lifespan of expensive laboratory instruments.

3. Improved Working Environment:

Uniform humidity levels contribute to a pleasant and safe working environment for employees.

Problems caused by improper humidity:

1. Impact on testing accuracy:

Humidity fluctuations can disrupt sensitive testing processes, compromise results, and undermine the credibility of experiments.

2. Damage to Technology:

Dry environments lead to electrostatic charge buildup, which can harm equipment like spectrometers and electron microscopes.

Uncontrolled conditions can significantly shorten the lifespan of costly technology.

3. Working Conditions:

Unstable humidity levels can negatively affect comfort and safety in the working environment.

Our solutions for laboratories:

Precise humidification: Stable humidity control with an accuracy of ±3% RH for optimal conditions.

Automated systems: Intelligent humidifiers that adapt to current environmental conditions.

Flexibility: Easy integration of systems into various laboratory environments.

Proper humidity control ensures reliable results, protects equipment, and fosters a healthy working environment. Contact us to find the best solution for your laboratory!

Automotive

Efficiency throughout the production process

Why is humidity control important?

In the automotive industry, many technological processes are influenced by air humidity, which plays a crucial role in ensuring quality and efficiency. From painting and assembly to plastic processing and parts storage, maintaining the right humidity level helps to:

Ensure material stability

Prevent electrostatic charges

Reduce dust accumulation

Improve working conditions

Benefits of our humidification systems:

Consistent Surface Quality: Optimal humidity ensures uniform paint application and a flawless finish.

Electrostatic Reduction: Maintaining 50–60% relative humidity prevents electrostatic buildup, minimizing disruptions in assembly and material handling.

Dust Control: Humidity binds dust particles, reducing contamination risks during production and storage.

Material Protection: Proper humidity levels prevent deformation of plastics, metals, and other components, preserving their integrity.

The impact of humidity on key processes:

1. Painting:

Maintaining 70% relative humidity prevents water evaporation from paints and reduces dust in the cabin.

Ensures uniform paint application for a flawless finish.

2. Plastics Processing:

Low humidity leads to electrostatic charges, which can disrupt precision in plastic part production.

Stable humidity enhances molding quality and minimizes defects.

3. Assembly:

Controlling electrostatic buildup is crucial when handling electronic components.

Improved working conditions contribute to higher employee productivity.

4. Parts & Component Storage:

Proper humidity levels prevent metal corrosion and plastic deformation.

Ensures parts remain in optimal condition for seamless assembly.

Our solutions for the automotive industry:

Precision Humidification: Customized technology designed for every stage of the production process.

Automated Control: Systems continuously adapt to environmental changes in real time.

Energy Efficiency: High-performance equipment with low operating costs.

Adaptability: Modular solutions for paint shops, assembly halls, and storage facilities.

Why choose our systems?

Our humidification systems create a stable environment that enhances production quality, minimizes downtime, and protects materials and finished products. Contact us today to learn how we can help optimize your production process!

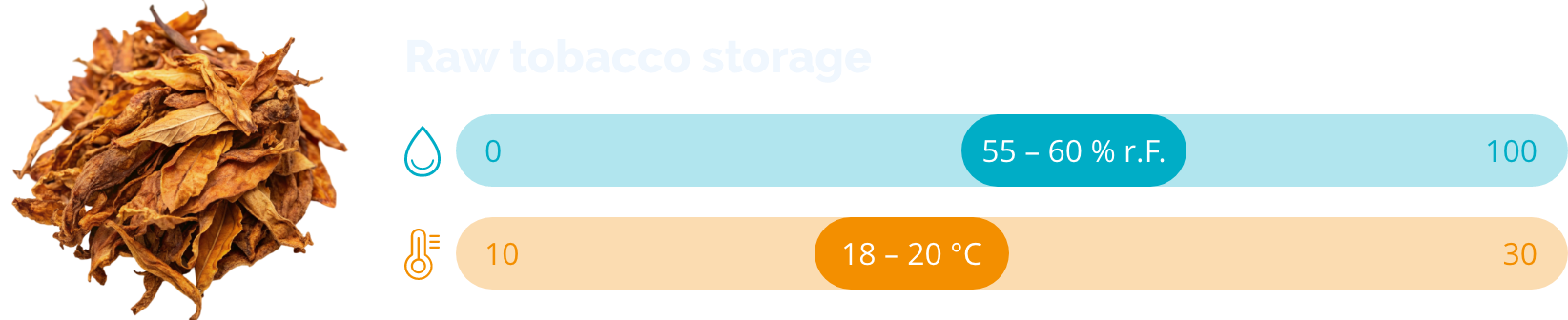

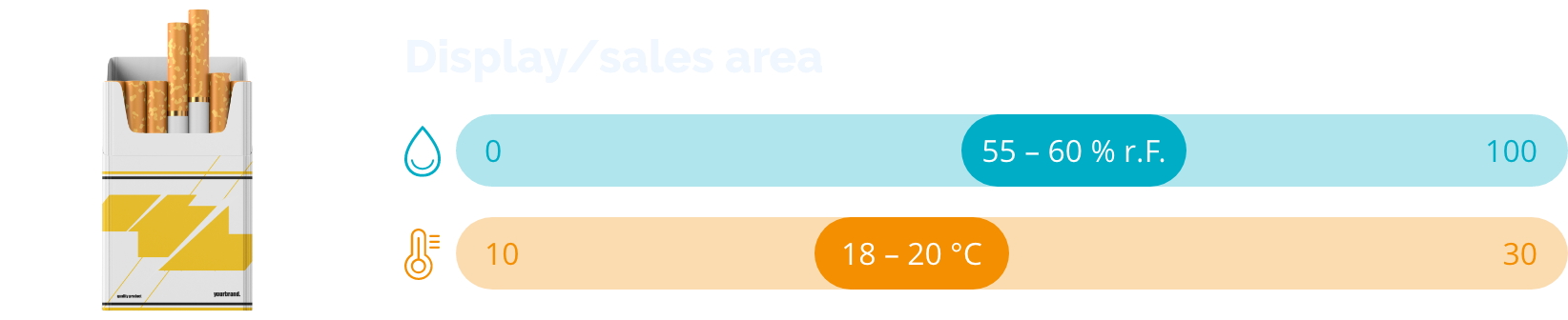

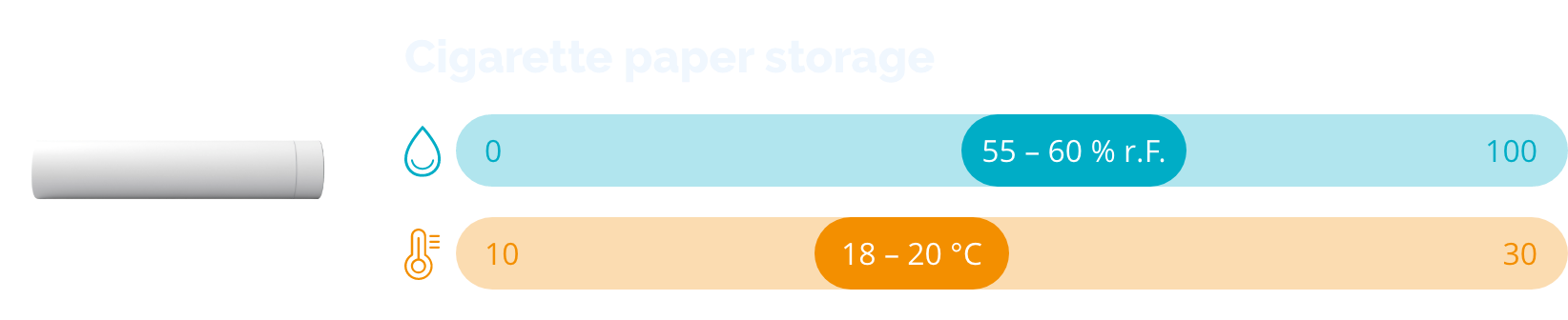

Tobacco

The key to perfect aroma

Why is the right humidity essential?

For tobacco enthusiasts, the quality of tobacco products relies heavily on proper storage. From cigarette papers and filters to premium cigars, each product requires the ideal environment to maintain its rich aroma and quality. Incorrect humidity levels can lead to:

Faster burning when smoked

Loss of flavor intensity

Degradation of tobacco leaf quality

Benefits of our humidification systems:

Aroma Preservation: The right humidity level ensures that tobacco retains its rich flavor and aroma.

Even Burning: Tobacco stored under optimal conditions burns slowly and evenly, enhancing the smoking experience.

Fermentation Support: Slow drying preserves cellular respiration and supports the chemical processes essential for fermentation.

Flexibility: Our systems can be tailored to all types of storage, from humidors to large warehouses.

Our solutions for tobacco storage and drying:

Precise Control: High-precision systems regulate both humidity and temperature, ensuring ideal conditions for drying and storage.

Automation: Advanced control systems continuously monitor and adjust to current requirements in real time.

Energy Efficiency: Designed for cost-effective operation, our systems provide excellent performance while keeping energy costs low.

Textile Industry

Optimal care for fibers and fabrics

Why is humidity control essential?

Textiles and yarns are highly sensitive to fluctuations in air humidity. When the air is too dry, fabrics lose moisture, leading to:

Brittle fibers

Shrinkage or excessive stretching, affecting fabric dimensions

Static buildup, which disrupts processing and impacts quality

Lower productivity and inconsistent product quality

Hygroscopic nature of fabrics

Textiles naturally absorb and release moisture based on the surrounding relative humidity. Let’s have a look at an example:

Cotton (weaving): 70–85% RH at 22–25°C

Wool (carding/combing): 65–80% RH at 20–25°C

Viscose (man-made fibers): 60–65% RH at 25–27°C

Benefits of our humidification systems:

Prevents Fiber Damage – Maintaining optimal humidity reduces the risk of fiber breakage and fabric irregularities.

Eliminates Electrostatic Charges – At 50–55% RH, static buildup is significantly reduced, improving material handling and processing efficiency.

Ensures Stable Quality – Consistent humidity levels help maintain fabric shape, integrity, and overall quality.

Customizable Solutions – Our systems adapt to the specific humidity needs of different textile processes, ensuring optimal conditions at every stage of production.

Impact on the production process:

Dust Reduction: By binding dust particles, humidity helps them settle on the ground, significantly reducing dust in the workspace.

Enhanced Processing: Maintaining optimal humidity prevents fiber separation, making combing, carding, and spinning processes smoother and more efficient.

Boosted Efficiency: Consistent humidity levels ensure uninterrupted production, minimizing downtime.

Our Solutions for the Textile Industry:

Precise Control: Our systems are engineered to maintain ideal conditions throughout every stage of the production process.

Real-Time Automation: The systems continuously adjust to current conditions, ensuring optimal performance at all times.

Cost-Effective Performance: We offer outstanding efficiency at a lower operating cost compared to alternative technologies.

Optimal humidity control is essential for producing high-quality textiles, streamlining production processes, and ensuring customer satisfaction. Reach out to us, and we’ll create a customized solution tailored to your business needs!

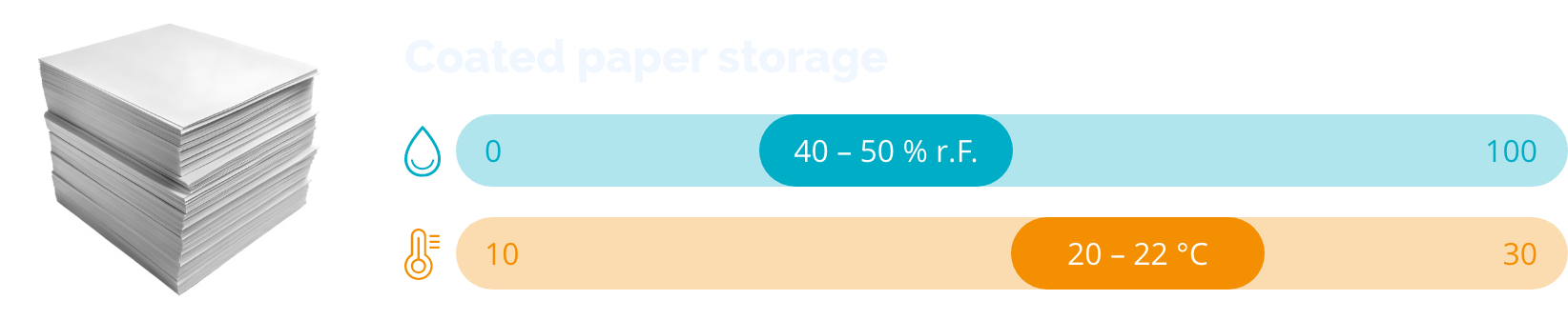

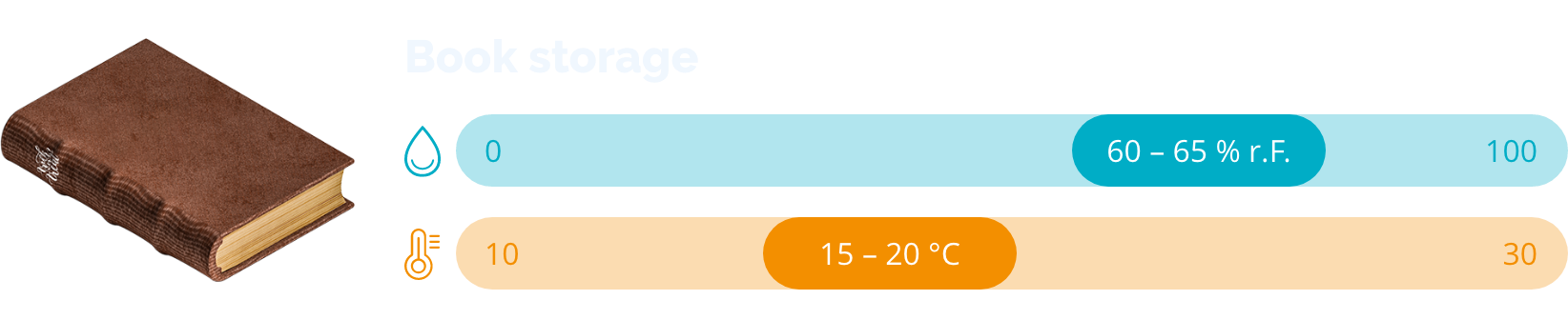

Printing Industry

The key to perfect results

The importance of correct humidity for the printing industry

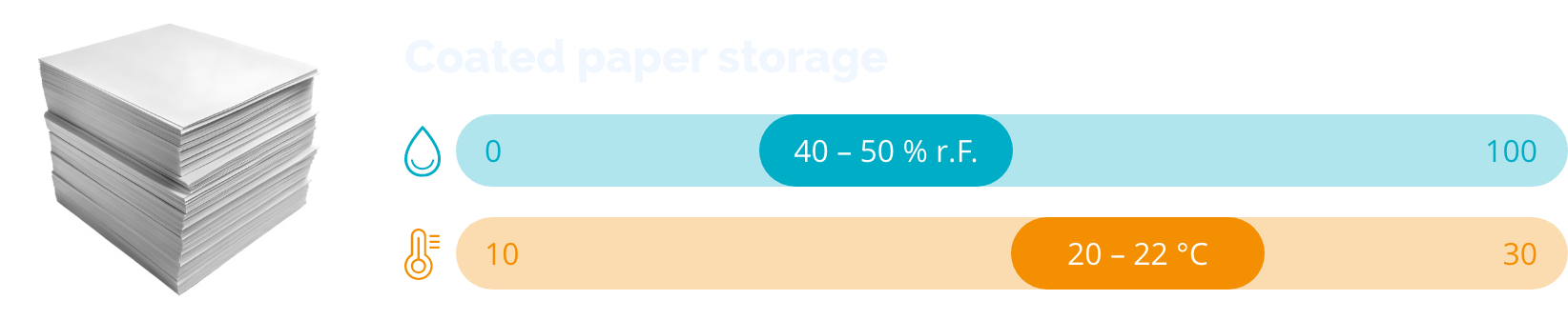

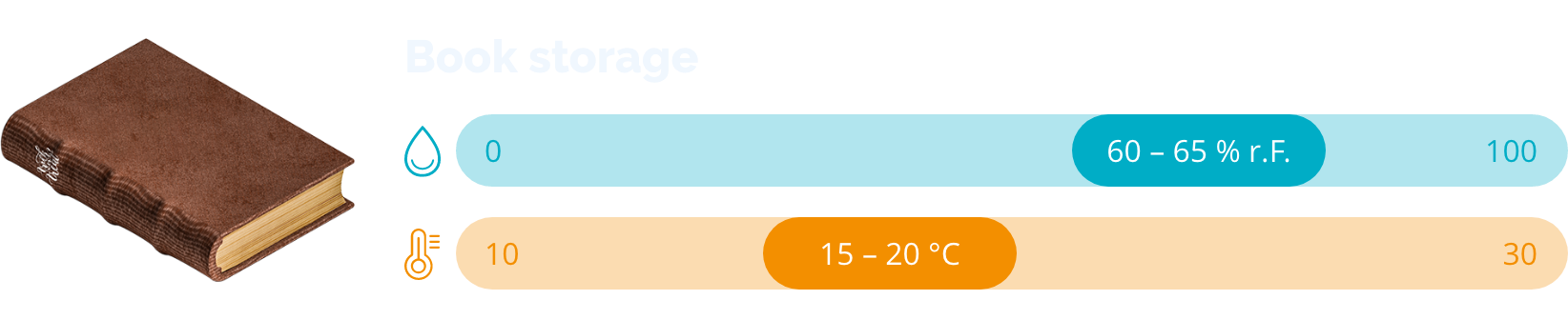

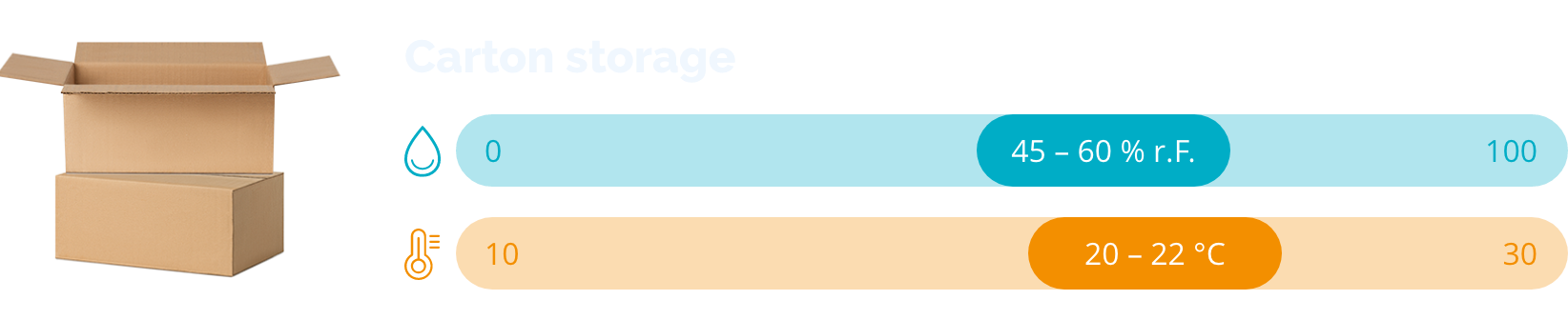

Despite the digital age, paper remains an essential part of everyday life. Whether it’s newspapers, books, packaging materials, insulation, or banknotes, paper and printed materials require precise storage and processing. Improper humidity levels can result in material damage, loss of quality, and inefficiencies in production processes.

Static charge and its impact on printing

When relative humidity drops below 40% RH, electrostatic charge can build up, leading to errors as paper passes through the machines. In contrast, maintaining humidity levels between 50–55% RH increases the conductivity of both the air and materials, effectively eliminating electrostatic charges.

Advantages of our humidification systems:

Eliminate Electrostatic Charge: Maintaining humidity at 50–55% RH increases air conductivity, preventing the buildup of electrostatic charges.

Increase Print Quality: Stable humidity at 60% RH and a temperature of 20–25 °C prevents paper misalignment and extends the lifespan of printing machines.

Reduce Dust: Increased humidity binds dust particles, causing them to settle and reducing contamination in printing processes.

Material Stability: Optimal humidity levels prevent paper deformation, shrinkage, and dimensional changes.

Perfect Printing Results

Modern printing systems—offset, digital, and web printing—require stable humidity levels for optimal performance. Without proper humidity control, dry air can cause:

- Paper misalignment

- Press downtime

- Reduced equipment lifespan. Our precision humidification systems maintain consistent humidity, eliminating these issues and enhancing production efficiency.

Paper misalignment

Press downtime

Preventing dust ingress

Dry air increases dust levels, which can compromise print quality and damage machinery. Maintaining humidity between 45–55% RH helps bind dust particles to moisture, causing them to settle rather than circulate in the air. This not only keeps the environment cleaner but also reduces maintenance needs.

Our Solutions:

Precision Control: Ensures stable humidity levels for optimal printing conditions.

Energy Efficiency: Delivers high performance with lower operating costs compared to traditional systems.

Flexible Design: Easily adapts to the specific requirements of printing facilities.

Maintaining the right humidity level is crucial for print quality, efficient production, and the long-term reliability of printing equipment. Get in touch with us, and we’ll help you find the perfect solution for your needs!

Woodworking industry

Humidification for wood protection and quality

The importance of humidity control in the woodworking industry

Wood is a natural material that retains its properties even after processing. However, under improper storage and processing conditions—particularly at low humidity—wood can lose its internal moisture. This results in deformations, cracks, and a decline in the quality of the final product.

Hygroscopic properties of wood

Wood naturally responds to changes in air humidity. When relative humidity drops below 40% RH, it loses moisture, resulting in cell damage and surface cracks. The ideal moisture content for wood processing is between 9–12%, which corresponds to an air humidity level of 50–60% RH.

Benefits of our humidification systems:

Wood Protection: Prevents warping, cracking, and dimensional changes during processing.

Stable Quality: Maintaining an ideal humidity level between 50-60% RH ensures a proper balance between wood and air.

Energy Savings: Our systems offer low operating costs compared to traditional humidifiers.

Dust Reduction: Eliminating dust contributes to a cleaner and healthier working environment.

Support for Water-Based Paints: Ensures optimal adhesion and surface quality.

Impact on production processes:

Dust Reduction: Humidity control minimizes excessive dust, leading to improved working conditions and reduced health risks.

Damage Prevention: Maintaining stable humidity helps prevent warping and dimensional changes during processing and storage.

Finish Quality: Proper humidity levels promote optimal results when using water-based paints.

Our Solutions:

Our advanced humidification systems use high-pressure water atomization to deliver uniform humidity at minimal cost. These automated, modular systems can be easily integrated into existing production facilities.

Paper industry

Optimal humidity for perfect results

Why is moisture control key?

In the paper industry, maintaining the right level of humidity is crucial for ensuring material quality and production efficiency. Given paper’s hygroscopic properties, precise environmental control is necessary to minimize deformation, reduce electrostatic charges, and prevent material loss.

Hygroscopic properties of paper

Paper naturally absorbs and releases moisture based on the surrounding environment. In low humidity, the air draws moisture from the material, causing brittleness and cracking. This effect is crucial not only for printing but also for the production of packaging materials.

Benefits of our humidification systems:

Healthy Working Environment: Eliminates dust and reduces electrostatic charges by up to 82%.

Material Protection: Minimizes warping and cracking by up to 70%.

Operational Efficiency: Increases productivity by 18%.

Modularity: Our systems are designed for easy expansion to accommodate additional production units.

Energy Savings: Maintaining humidity in winter reduces heating costs by improving the perceived temperature by up to 10%.

The effect of humidity on paper and processes:

Electrostatics: Low humidity generates electrostatic charges that can disrupt the smooth operation of printing presses and material handling.

Paper Distortion: Insufficient humidity causes dimensional changes, deformation, and issues in paper processing.

Quality of Results: Maintaining stable humidity (50-60% RH) minimizes production downtime, reduces costs, and enhances quality standards.

Our solutions for the paper industry:

Direct Air Humidification: Our systems provide uniform humidity throughout the entire space.

Automated Control: Intelligent systems adjust humidity to meet current needs.

Energy Efficiency: Enjoy lower operating and maintenance costs.

With our humidification systems, you achieve a stable environment for optimal results, minimizing downtime and maximizing profitability. Contact us, and we will find a solution tailored to your needs!

Case Studies

Explore successful implementations of our systems in practice.

Humidification in the wood processing industry

A humidification system featuring 42 nozzles has been installed in a wood processing plant, delivering approximately 120 liters of water per hour. This water vapor maintains relative humidity levels between 45-55%, which is ideal for working with wood. Consequently, the wood achieves optimal humidity levels of 10-15%, ensuring stable product quality.

System benefits

Improved working environment: Humidification reduces airborne dust and enhances conditions for employees.

Healthier environment: Maintaining optimal humidity levels helps minimize the occurrence of respiratory issues.

Eco-friendly technology: This system boasts low energy consumption compared to steam humidifiers, which require significantly more energy.

Dust reduction in the production of hygienic paper products – BM Plus spol. s r.o.

Problem:

BM Plus, a manufacturer of hygienic paper products, encountered significant issues with elevated dust levels in its new production line. This not only affected the efficiency of production processes but also posed health and safety risks for employees. Traditional dust reduction methods were financially and logistically challenging, prompting the company to seek a more effective solution.

Solution:

SANFOG s.r.o. designed and installed a high-pressure spray system that effectively reduced dust levels in the production hall. This system not only enhanced air quality but also fostered a healthier working environment, enabling the company to secure more favorable insurance terms and lower operating costs.

Results

Significant reduction in dust levels.

Improved conditions for employees’ health and safety.

Cost savings achieved through better insurance conditions.

Increased efficiency of production processes.

The project was completed in record time, ensuring that production remained uninterrupted. The professionalism and expertise of the SANFOG s.r.o. team surpassed the expectations of BM Plus.

Solution:

The project was completed in record time, ensuring that production remained uninterrupted. The professionalism and expertise of the SANFOG s.r.o. team surpassed the expectations of BM Plus.

Air humidification and cooling

Summer season – adiabatic cooling

The adiabatic cooling system effectively lowers temperatures in production halls while maintaining minimal operating costs. For a hall with a volume of 29,250 m³ and a power output of 362 kW, significant savings can be reached compared to conventional air conditioning. On average, energy savings can reach up to €220 per day during daily operations. Over a summer season lasting 130 days, this translates to an impressive total savings of €28,600.

Winter season – humidification

In winter, maintaining optimal humidity levels at 55% significantly reduces the need for heating. By ensuring proper humidity, you can lower temperature settings while still keeping employees comfortable, leading to reduced heating costs. The annual savings on heating from installing a humidification system can reach up to €43,890.

Other Benefits

Reduced employee absenteeism thanks to a healthier working environment.

Improved quality of processed materials by 5%.

Decreased static electricity in production areas.

Improved efficiency of production processes.

The project was completed in record time, ensuring that production remained uninterrupted. The professionalism and expertise of the SANFOG s.r.o. team surpassed the expectations of BM Plus.

Winter season – humidification

The project was completed in record time, ensuring that production remained uninterrupted. The professionalism and expertise of the SANFOG s.r.o. team surpassed the expectations of BM Plus.